Teak Deck

INTRODUCTION TO THE TEAK WOOD

Teak wood is well known for its natural durability and why it is used to make furniture or elements that will be outdoors.

It is one of the best-known tropical woods on the market and among its multiple uses stand out for shipbuilding and for outdoor and luxury furniture.

Teak wood (Tectona grandis) is native to Southeast Asia, where it can reach heights of up to 40 metres.

Teak has been used for hundreds of years as a building material for boat decks. As it is a very hard wood that can withstand very well the inclement weather, it is ideal for the construction of roofs and outdoor furniture.

One of the reasons that also makes it very suitable for building boat decks, is the fact that its wood has natural antimicrobial and insecticide substances. They make it an excellent natural anti-potency be havior, high resistance to weathering and also have the benefit of certain insects and fungi not spoil it easily.

TYPE OF TEAK DECK

The types of deck can be distinguished by the material in which they are made.

Below, we detail the two types that we can find.

Deck of natural teak

Natural teak is one of the best known tropical woods and treated for both naval use and outdoor furniture.

This wood has a long durability and if properly maintained, will always be as good as new.

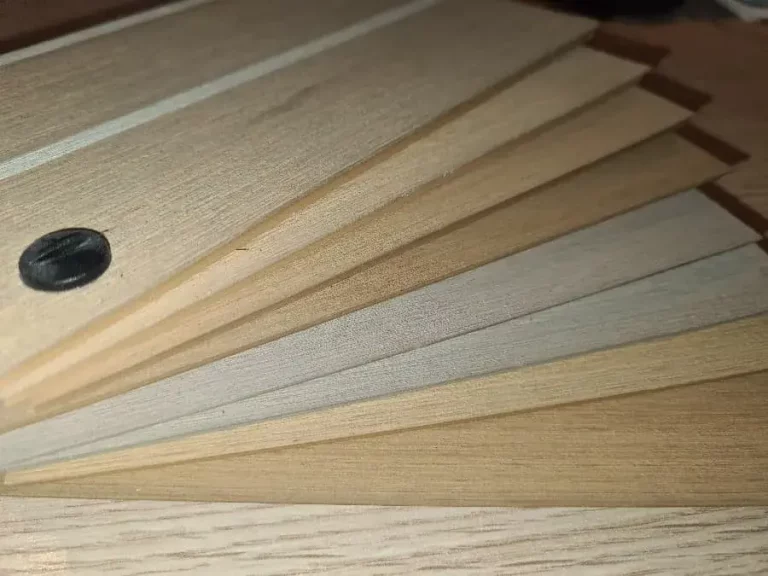

Teak wood slats can be of various widths and thicknesses.

The most common widths for making teak covers are 15, 12, 10 and 8 mm.

The caulking we offer can be both black or white.

Deck of synthetic teak

Flexiteak is a non-porous material, similar in appearance to wood, but with the advantage that it does not require as much maintenance as that of natural teak and the colors have greater durability.

This material helps not to slip so easily and has a lighter weight than wood.

The caulking is already integrated and can be in two colours, black or white.

Below you can see the different samples of this material.

MANUFACTURING TECHNICAL DECK

Our process when installing a teak deck is as follows

Template of the deck

First, we must make the templates or patterns of the deck, manually or digitally, taking sizes from all parts: corners, possible curves, etc. The patterns help us to do the work in our workshop and do it exactly to what the boat requires.

This pattern made with templates can be made in one piece or if it is a very large process, we can make it in different pieces and finally put it all together at the time of installation.

As you can see in the example below, it has a covering process where we’re working directly with the templates we made.

Prefabrication of the floor

Once we’ve the templates made we proceed to prefabricate and design the roofs in the workshop using our specialized machinery.

It is at this point when we will glue the teak strips together, to create a joint piece. In this way we obtain a single solid piece that speeds up the process of installing the floor.

Once we have the deck made in the workshop we will install them on the boat.

INSTALLATION OF THE TEAK DECK

When we have the teak piece made, either from the deck, stern platform, . . . or all the parts manufactured separately, we proceed to install them.

Installation requires precision and accuracy to the millimetre, as not even a small error is allowed, because it is completely custom made.

By working in this way, we manage to reduce installation and manufacturing time.

Once all the parts are installed, we perform the caulking.

Caulking of the teak deck

The caulking of the cover can be done in three colours: black, white and grey (the latter being the least used)

Here are two examples of caulking:

Caulking is the process in which we fill the joints between the strips with a kind of elastic rubber. In this process, we will be strengthening the entire structure, while protecting and waterproofing the entire floor.

First, we will apply primer to the joints, in this way we will facilitate the adhesion of the products that we will have to apply afterwards.

When the primer has dried, respecting the times set by the manufacturers, we proceed to fill the seals with TDS (Teak Deak Sis).

Once the joints are full, we will have to wait for the material to dry, following the manufacturer’s guidelines and then we will polish the entire cover to remove the remaining rubber remains and thus leave the entire surface of the cover level and without imperfections.

MAINTENANCE OF TEAK DECK

Periodically the natural teak covers must be maintained if we want them to last years in perfect condition and look like the first day.

No matter how resistant and durable the teak is, the UV rays of the sun, the salt of the sea and the inclement weather will cause our teak cover, little by little, to lose its original colour and start to take on more greyish tones, etc.

Cleaning of the teak deck

At least two times a year we should carry out a thorough cleaning to prevent the creation of bacteria that can damage the wood.

The process is simple, it should be cleaned with a special product for teak, rubbing with a brush that is not very aggressive, this way we will not damage the wood.

Many times by using a brush that is not suitable, with very hard spikes, we will be wearing the surface of the cover.

Polishing of the teak deck

If we want the teak to look like the first day, once thoroughly cleaned, it should always be polished with special teak products.

We will be returning the original bright colour of the teak and helping to keep it in perfect condition.

Nourishing the wood of the teak deck

When we have the shiny cover like the first day, we will need nourish the teak with a special oil, this oil maintains its properties and make it last longer as new.